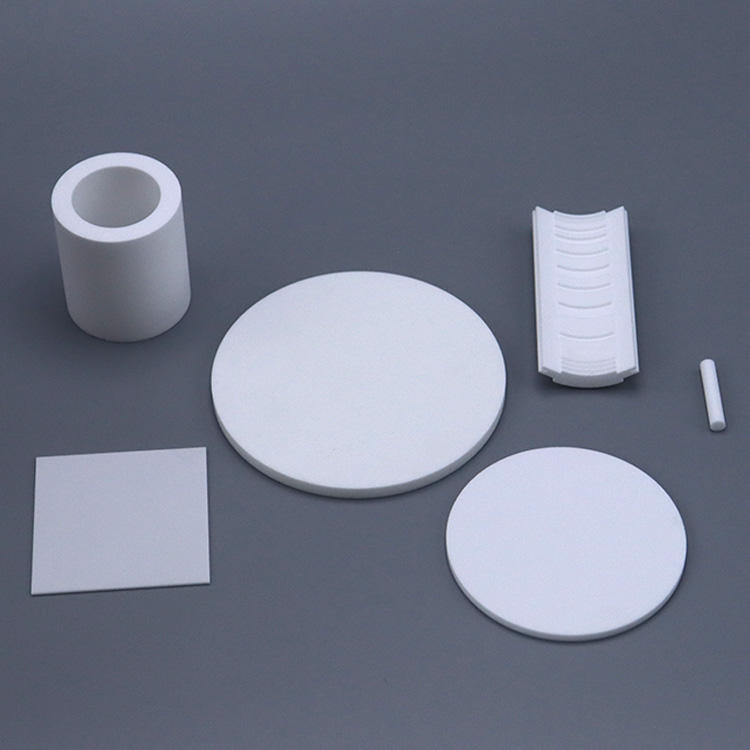

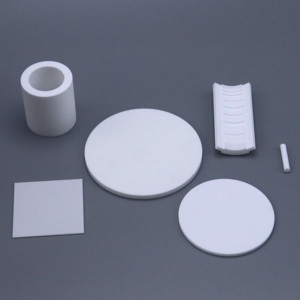

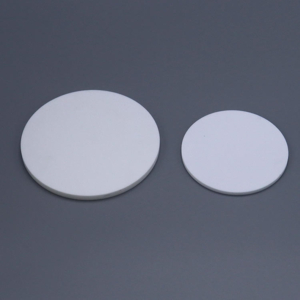

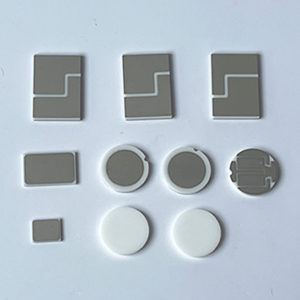

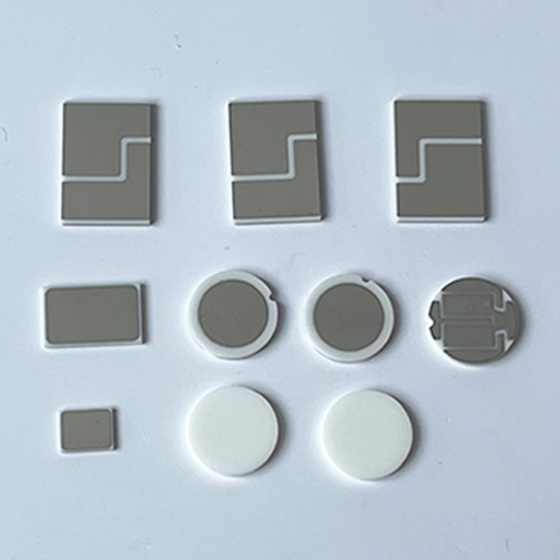

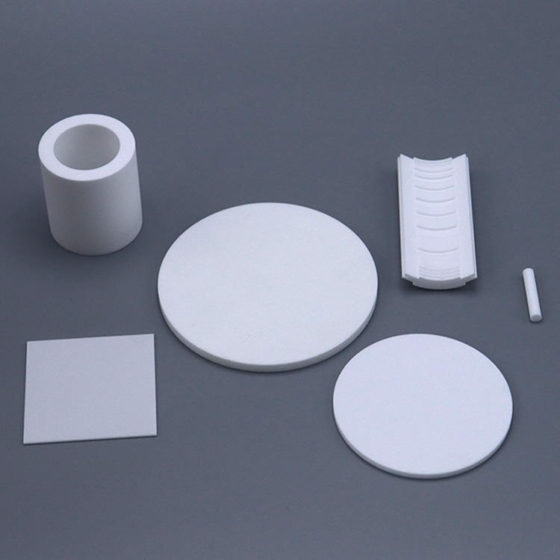

High Performance Semiconductor Beryllium Beo Ceramic Disc Plate

High Performance Semiconductor Beryllium Beo Ceramic Disc Plate

High Performance BeO Ceramic Plate with Excellent Thermal Conductivity for Semiconductor & Electronic Devices

Beryllium Oxide Ceramic

Beryllium Oxide Ceramic

Beryllium oxide (BeO) ceramic is a high-performance advanced material known for its exceptional thermal conductivity and stability at high temperatures. It has a melting point ranging from 2530°C to 2570°C and a theoretical density of 3.02 g/cm³.

BeO ceramics can operate continuously at:

1800°C in vacuum,

2000°C in inert gas,

and remain stable up to 1800°C in oxidizing environments without volatilization.

The most remarkable property of beryllium oxide is its extremely high thermal conductivity, which is comparable to that of metallic aluminum and 6 to 10 times higher than alumina (Al₂O₃).

In addition to its thermal advantages, BeO ceramic is an excellent dielectric material with a unique combination of electrical insulation, thermal conductivity, and mechanical strength. No other ceramic material offers such a well-balanced and comprehensive performance profile, making it ideal for demanding applications in electronics, aerospace, and high-temperature systems.

Attributes

| Attribute 1 | Value 1 | Attribute 2 | Value 2 |

| Material | Beryllium oxide ceramic | Place of Origin | Guangdong, China |

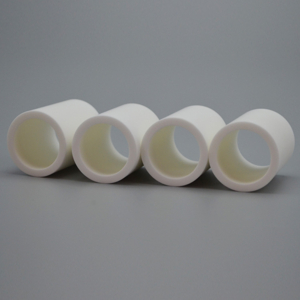

| Type | Ceramic Rods | Application | Refractory |

| Model Number | GIM-9785 | Brand Name | GIM |

| Color | White | Thermal Conductivity | >35W/m.k |

| Width | 20-500mm | Alumina Content | 75-99.7% Available |

| Feature | Eco-friendly | Thickness | 1-60mm |

| Brand | Xingtailong | Certification | ISO9001-2008/CE |

| Shape | Can be requested | Sample | Free available |

| Selling Units | Single item | Single package size | 35X25X35 cm |

| Single gross weight | 3.000 KG |

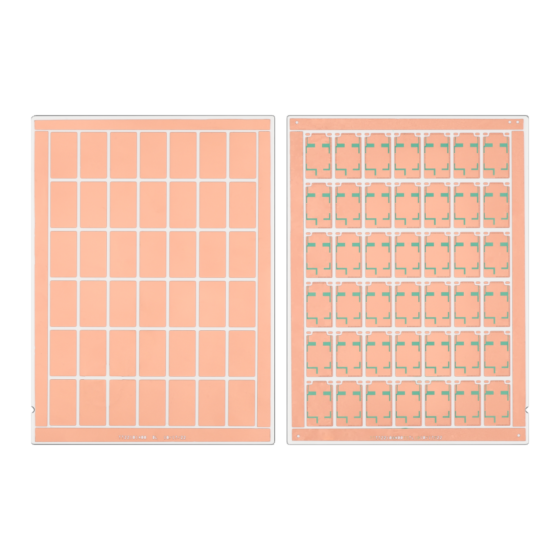

✅ Applications of Beryllium Oxide (BeO) Ceramic

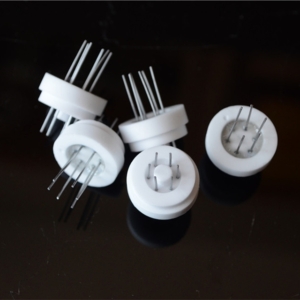

Electronics & Semiconductors

Beryllium oxide is widely used in the production of high-power electronic devices—such as transistors, diodes, and integrated circuits—where superior heat dissipation is essential to maintain performance and reliability.Nuclear Industry

Thanks to its excellent thermal conductivity and high neutron transparency, BeO ceramic is employed as a moderator, insulator, and structural material in nuclear reactors and related systems.Aerospace & Defense

In harsh environments involving high temperatures, vibrations, and radiation, BeO provides a reliable solution for thermal management and electrical insulation in sensitive components and subsystems.Medical Equipment

BeO ceramics are utilized in advanced medical imaging systems (e.g., CT scanners, MRI units) and diagnostic devices where precise thermal control and electrical insulation are critical for safety and accuracy.

Laser Systems

Owing to its high thermal conductivity and low thermal expansion, beryllium oxide is used as a substrate or heat sink in high-power laser systems, ensuring stability and performance under thermal load.Thermal Management Solutions

BeO ceramics are ideal for applications requiring efficient heat transfer, including heat sinks, thermal spreaders, and heat exchangers, especially in compact or high-performance systems.

Properties of Beryllium Oxide (BeO) for Industrial Applications

| Properties of Beryllium Oxide (BeO) for Industrial Applications | ||

| Property Type | Property | Description |

| Physical | Density | 3.01 g/cc, lighter than alumina |

| Hardness & Strength | Comparable to silicon carbide and boron nitride | |

| Fracture Toughness | Lower than alumina, offset by high thermal conductivity | |

| Chemical | Stability | Resistant to most acids, bases, and molten metals |

| Reactivity | Reacts with water vapor above 1000 | |

| Thermal Shock | Excellent resistance to rapid temperature changes | |

| Thermal | Conductivity | Up to 330 W/mK, among the highest for ceramics |

| Electrical | Dielectric Strength | 10-16 kV/mm, ideal for high voltage applications

|

| Dielectric Constant | Low, beneficial for high-frequency electronic applications | |

Industry Resources & References

Explore trusted global resources and organizations related to advanced ceramics and precision material applications across various industries.

Advanced Materials

Learn more about the latest trends in advanced ceramics and precision materials from

AZoM,

a global materials science hub that provides insights into innovations, applications, and manufacturing technologies.

Aerospace Industry

The aerospace industry relies heavily on high-performance ceramics. Visit

NASA

to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

Electronics Industry

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance.

IEEE

is a trusted global organization that drives innovation in electrical and electronic engineering.

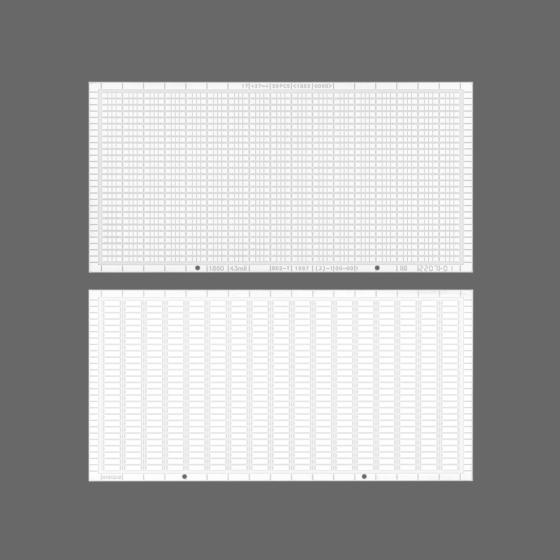

Semiconductor Industry

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the

Semiconductor Industry Association (SIA).

Automotive Industry

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries.

Visit SAE International

for standards and innovations driving automotive engineering forward.

Medical & Healthcare

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance.

The U.S. FDA Medical Devices Center

provides regulatory and research information in this field.

New Energy

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics.

Visit the U.S. Department of Energy (DOE)

for innovations and materials research in sustainable energy technologies.