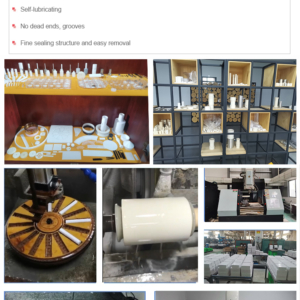

Al2O3 Ceramic Piston and Plunger Set – High Strength & Chemical Resistance for Pumps

Al2O3 Ceramic Piston and Plunger Set – High Strength & Chemical Resistance for Pumps

Wear and Corrosion Resistant Al2o3 Alumina Ceramic Piston Plunger Bushing Rod for High Pressure Pump

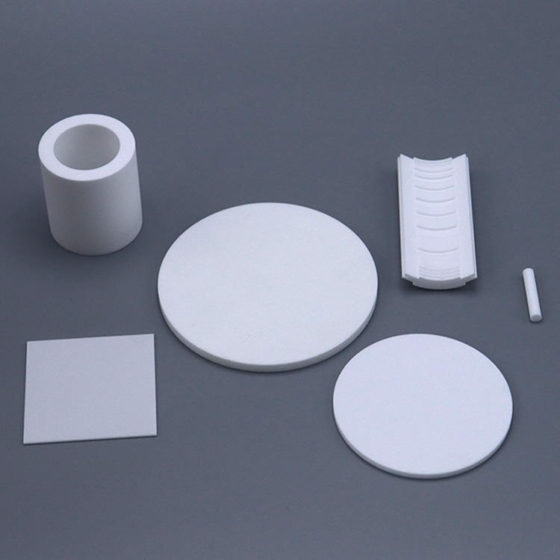

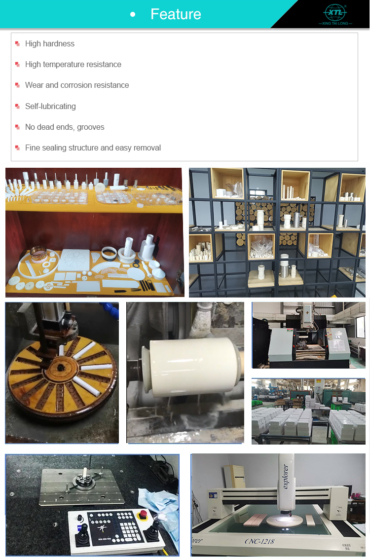

Features of ceramic:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)…

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1….

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm…

4. High Polished Surface Up To Rz0.8(Ra0.1) …

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength…

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance…

8. Long Service Life…

9. Other excellent property

Application

Application

These are typically used in jet pumps, water jetting pumps, high pressure pumps and high pressure

water supply pumps, which find tremendous applications in industries including automobiles, chemical

and petrochemicals, foundries, oil refineries, paper and pulp manufacture, cement manufacturing, food

processing, thermal power plants and steel plants etc.

Alumina Ceramic Plunger – Product Specification Sheet

| Attributes | Details |

|---|---|

| Product Name | Ceramic Plunger |

| Material | 95% – 99% Alumina Ceramic |

| Place of Origin | Guangdong, China |

| Brand Name | GIM |

| Model Number | 2021070-01 |

| Type | Ceramic Tubes |

| Application | Industrial Ceramic / Wear-Resisting Parts |

| Processing Service | Cutting |

| Shape | As per Drawing Requirements |

| Color | White & Light Yellow |

| Fit Tolerance | ±0.005 mm |

| Density | 3.8 g/cm³ |

| Max Working Temperature | 1650°C – 1700°C |

| Features | High Wear Resistance, High Temperature Resistance |

| Usage | Wear-Resisting Applications |

| Package | Individually Safe Packaging |

| Selling Units | Single Item |

| Single Package Size | 35 × 25 × 25 cm |

| Single Gross Weight | 3.000 kg |

✅Contact us:

website: www.nmmech.com

Email: jack@nmmech.com

More industry information:

🌐 1. Advanced Materials / Precision Ceramics

External Link: https://www.azom.com

Description :

Learn more about the latest trends in advanced ceramics and precision materials from AZoM, a global materials science hub that provides insights into material innovations, applications, and manufacturing technologies.

🚀 2. Aerospace Industry

External Link: https://www.nasa.gov

Description:

The aerospace industry relies heavily on high-performance ceramics. Visit NASA to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

⚙️ 3. Electronics Industry

External Link: https://www.ieee.org

Description:

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance. IEEE is a trusted global organization that drives innovation in electrical and electronic engineering.

💡 4. Semiconductor Industry

External Link: https://www.semiconductors.org

Description:

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the Semiconductor Industry Association (SIA).

🚗 5. Automotive Industry

External Link: https://www.sae.org

Description:

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries. Visit SAE International for standards and innovations driving automotive engineering forward.

🏥 6. Medical & Healthcare

External Link: https://www.fda.gov/medical-devices

Description:

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance. The U.S. FDA Medical Devices Center provides regulatory and research information in this field.

⚡ 7. New Energy / Renewable Energy

External Link: https://www.energy.gov

Description:

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics. Visit the U.S. Department of Energy (DOE) for innovations and materials research in sustainable energy technologies.

GIM

GIM