Unveiling Advanced Ceramic Substrate Polishing Techniques:

How to Achieve Ra 3.00 nm on AlN?

With the rapid development of the electronics industry, the market has set increasingly stringent standards for ceramic substrates, especially in terms of surface roughness and flatness. To meet these demands, ceramic substrate manufacturers have been extensively researching various polishing techniques to achieve superior surface precision.

Through years of exploration, it has become clear: due to the differences in the physical properties and microstructures of ceramic materials, selecting the appropriate polishing method is essential to achieve high-efficiency and high-precision results.

So, how do you polish an AlN ceramic substrate to reach an ultra-smooth Ra of 3.00 nm?

Let’s explore the latest and most effective ceramic polishing technologies!

Common Polishing Methods for Ceramic Substrates

Today, several advanced polishing techniques are widely applied to ceramic substrates, including:

- Chemical Mechanical Polishing (CMP)

- Abrasive Flow Polishing

- Ultrasonic Vibration-Assisted Abrasive Flow Polishing

- Electrophoretic Polishing

- Electrolytic Polishing

- Magnetorheological Polishing (MRF)

Based on how the polishing tool interacts with the substrate, these techniques are classified into:

- Contact Polishing

- Non-Contact Polishing

- Hybrid Techniques (combining both contact and non-contact effects)

Each ceramic material and its surface quality requirement calls for a specific or hybrid polishing strategy.

1. Mechanical Polishing

Mechanical polishing removes material through abrasive grinding and rolling actions, often performed manually using oil stones, wool wheels, and sandpaper. For components requiring high surface quality, ultra-fine lapping can be used to reach surface roughness as low as Ra 0.008 µm.

However, this method can induce stress and thermal deformation, especially at high temperatures. Therefore, temperature control is critical during the polishing process.

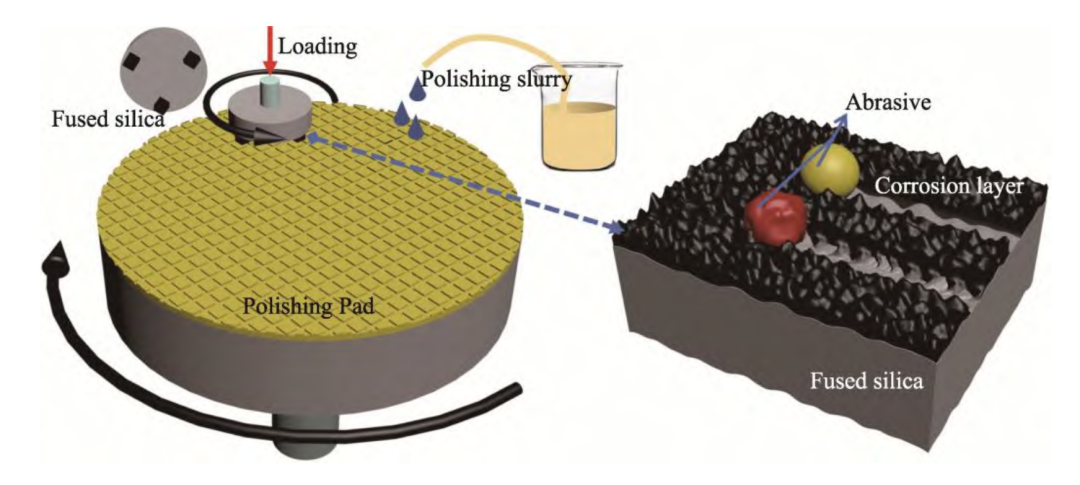

2. Chemical Mechanical Polishing (CMP)

CMP integrates chemical reactions with mechanical action to achieve global planarization. It offers nanometer-level surface precision and minimal sub-surface damage, making it ideal for materials like Al2O3, SiC, Si3N4, and AlN.

During CMP, the slurry reacts with the substrate surface, softening it for mechanical removal. Proper adjustment of slurry composition and polishing parameters ensures defect-free and highly polished surfaces.

Non-Contact Polishing Methods

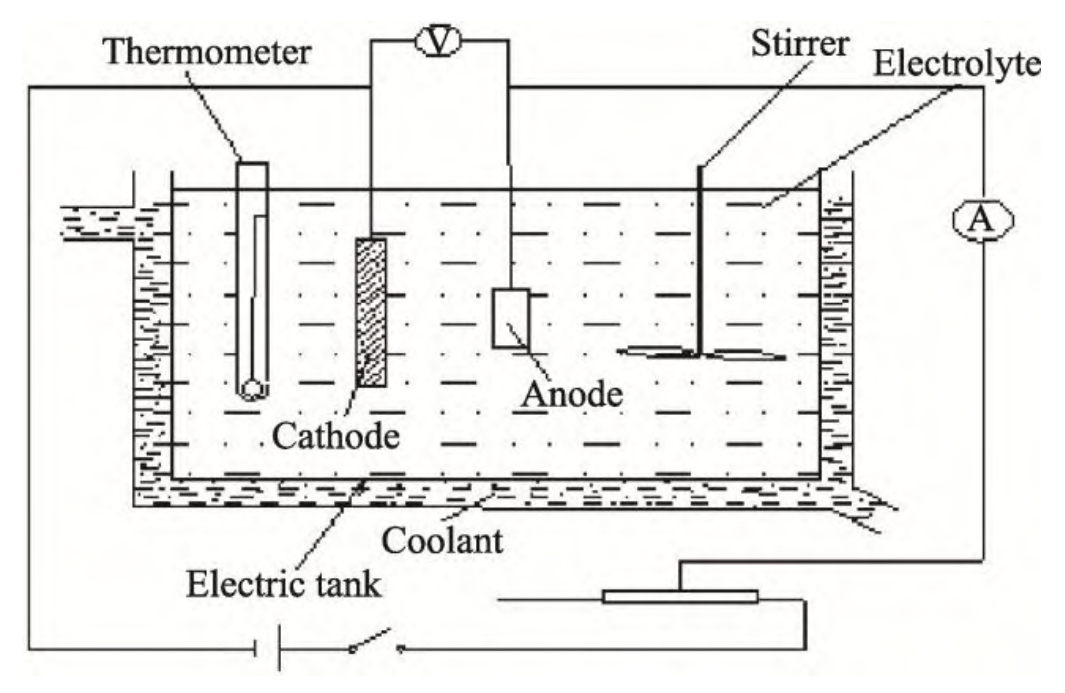

3. Electrolytic Polishing

Electrolytic polishing selectively dissolves surface asperities through electrochemical reactions. A metal workpiece is made the anode in an electrolytic cell, resulting in a smoother surface. This technique is simple, efficient, and well-suited for polishing SiC substrates.

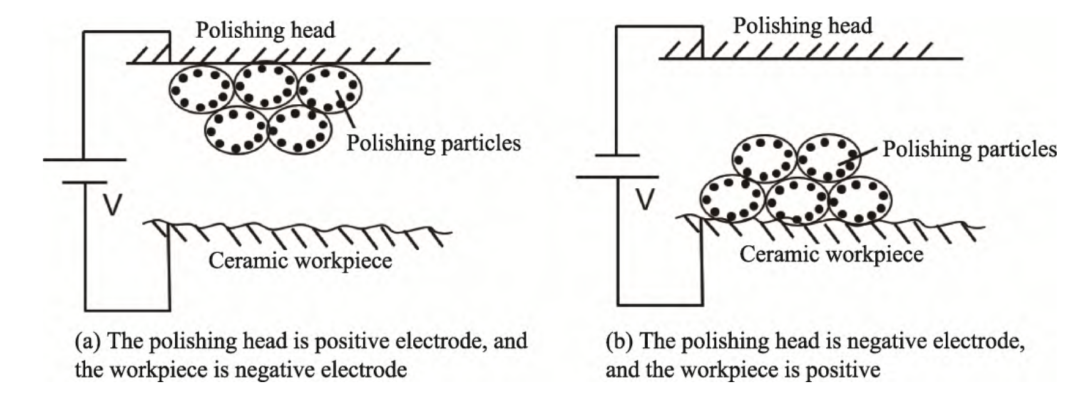

4. Electrophoretic Polishing

This technique uses electric fields to guide charged abrasive particles onto the workpiece surface. Depending on electrode polarity, particles migrate and polish the surface through soft friction and impact.

It causes minimal mechanical damage, making it ideal for ultra-precision polishing of functional ceramics.

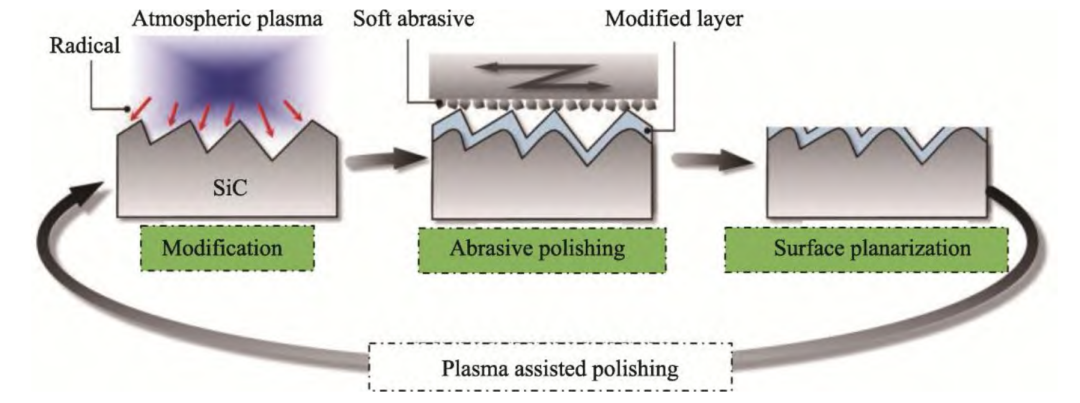

5. Plasma-Assisted Polishing (PAP)

Proposed in 2010 by Yamamura at Osaka University, PAP is a dry polishing method combining chemical surface modification via plasma irradiation and mechanical removal via soft abrasives.

This technique achieves atomically flat surfaces with minimal sub-surface damage, and has been successfully applied to SiC and AlN.

Hybrid Polishing Technologies

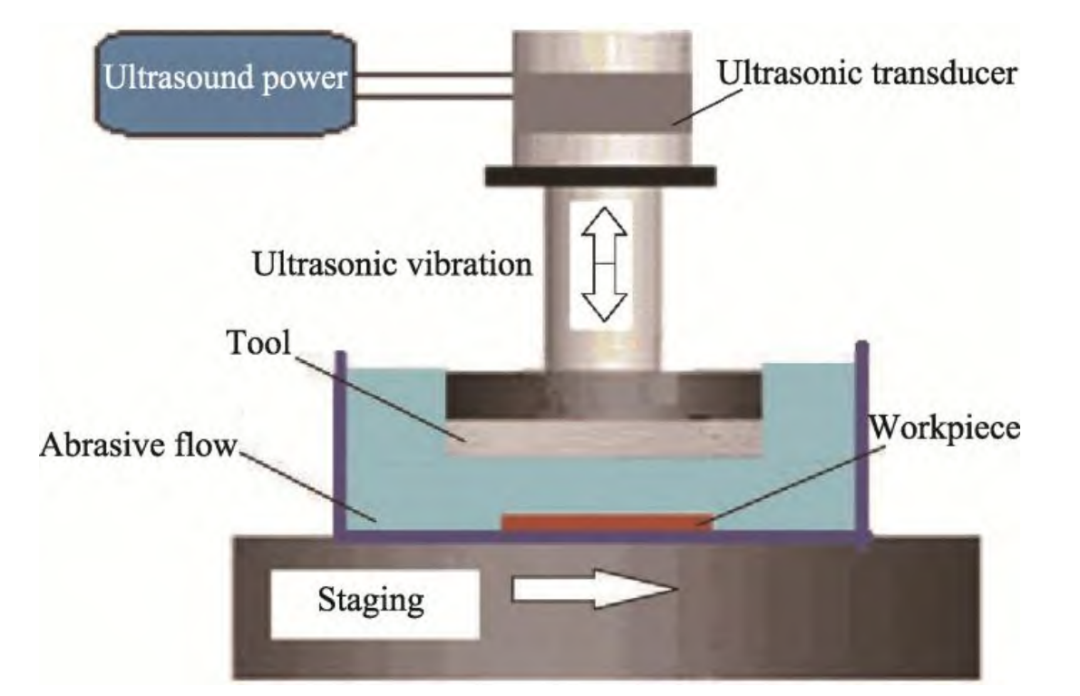

6. Ultrasonic Vibration-Assisted Abrasive Flow Polishing (UVAFP)

UVAFP enhances material removal by combining abrasive flow and ultrasonic vibration. The high-frequency vibration improves impact and polishing efficiency, enabling precise surface finishing, especially for AlN substrates.

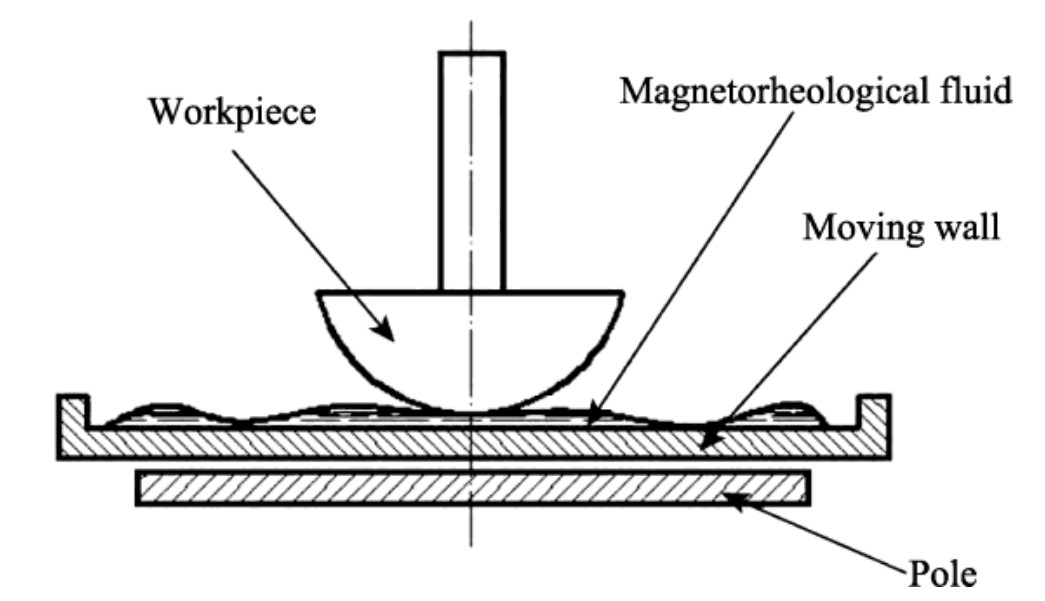

7. Magnetorheological Polishing (MRF)

MRF employs a fluid containing magnetic particles that changes viscosity under a magnetic field. This fluid flows through a narrow gap between the workpiece and a rotating disk, generating strong shear forces that polish the surface.

With high precision, controllable force, and minimal damage, MRF is ideal for optical components and small-diameter ceramic parts.

Matching Polishing Techniques to Ceramic Materials

Common ceramic substrates include:

- Aluminum Oxide (Al2O3)

- Aluminum Nitride (AlN)

- Silicon Carbide (SiC)

- Silicon Nitride (Si3N4)

- Beryllium Oxide (BeO)

Among these, Al2O3, AlN, and SiC have well-established polishing research and practices. By contrast, polishing methods for Si3N4 and BeO are still under active exploration.

Ultimately, selecting the right polishing method—or combining multiple techniques—is the key to producing high-quality ceramic substrates ready for next-generation electronics applications.

Learn more about ceramic materials

The American Ceramic Society, ACerS)

👉 https://ceramics.org/Materials Project – Alumina Database (Lawrence Berkeley National Laboratory)

👉 https://materialsproject.org/materials/mp-1143/NASA Technical Reports – Ceramic Substrates in Electronics

👉 https://ntrs.nasa.gov/IEEE Xplore Digital Library (Electronics & Substrate Research)

👉 https://ieeexplore.ieee.org/AZoM – Alumina (Aluminum Oxide) Material Information

👉 https://www.azom.com/article.aspx?ArticleID=52

Conclusion

GreenIM™ alumina substrates provide the perfect balance of cost-effectiveness, thermal performance, and dielectric reliability. Whether used in semiconductor packaging, RF communication, or power electronics, GreenIM™ delivers a trusted solution for advanced applications.

Contact Us

👉Website: nmmech.com

👉Email: jack@nmmech.com

GIM

GIM