GreenIM™Advanced Alumina Substrates | High Performance Ceramic Materials

What is GreenIM™ Alumina Substrate?

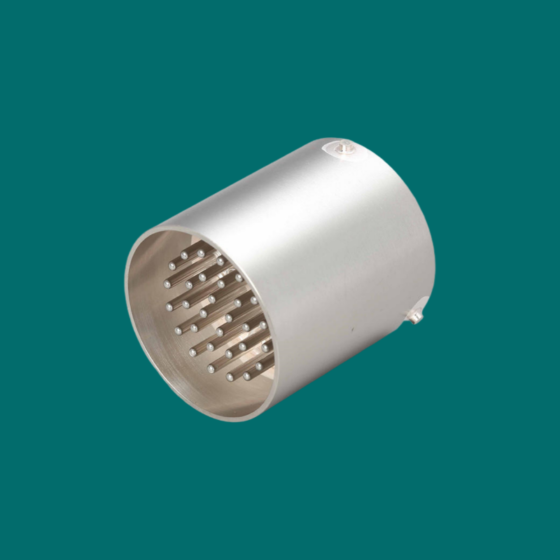

GreenIM™ alumina substrates are advanced ceramic materials designed for semiconductor, electronics, and high-power applications. With excellent thermal conductivity, dielectric strength, and mechanical stability, GreenIM™ offers reliable performance in demanding environments.

Compared with conventional Al₂O₃ ceramic substrates, GreenIM™ ensures superior electrical insulation, low dielectric loss, and exceptional surface quality, making it an ideal choice for next-generation electronic packaging.

Key Features of GreenIM™ Substrates

High Purity Alumina (≥ 99.6%) – ensures consistent electrical and thermal performance.

Excellent Thermal Conductivity – ideal for heat dissipation in high-power devices.

High Dielectric Strength – reliable insulation for semiconductor circuits.

Outstanding Mechanical Properties – high strength and resistance to wear and corrosion.

Precision Surface Finish – compatible with thin film, thick film, and metallization processes.

Applications of GreenIM™ Alumina Substrates

GreenIM™ substrates are widely used across industries that require high precision and reliability:

Semiconductor packaging – IC substrates, power modules, and LED packaging.

High-frequency electronics – microwave devices, 5G communication, and RF modules.

Automotive electronics – EV power control units and high-voltage insulation.

Aerospace & defense – radar systems, sensors, and avionics.

Medical devices – implantable electronics and diagnostic instruments.

Explore more advanced ceramic applications

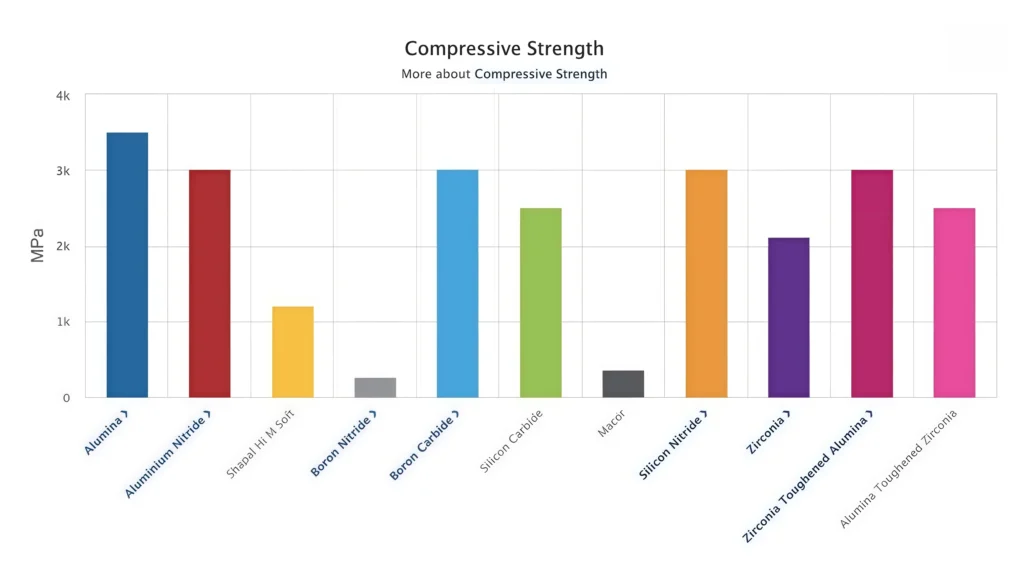

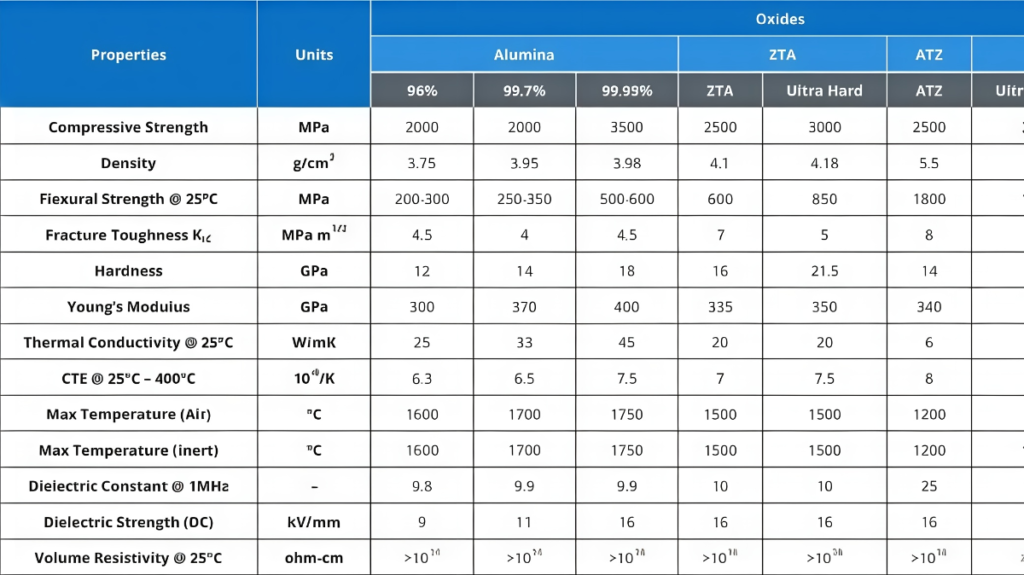

GreenIM™ vs. Other Ceramic Substrates

| Property | Alumox™ (Al₂O₃) | AlN Substrate | Si₃N₄ Substrate |

|---|---|---|---|

| Thermal Conductivity | ★★★☆ | ★★★★ | ★★★ |

| Dielectric Strength | ★★★★ | ★★★ | ★★★☆ |

| Mechanical Strength | ★★★ | ★★★ | ★★★★ |

| Cost-Effectiveness | ★★★★ | ★★ | ★★☆ |

For applications requiring high thermal conductivity, AlN substrates may be recommended, while Si₃N₄ substrates provide higher mechanical toughness. However, GreenIM™ substrates balance cost, reliability, and performance, making them suitable for most industrial and electronic applications.

For applications requiring high thermal conductivity, AlN substrates may be recommended, while Si₃N₄ substrates provide higher mechanical toughness. However, GreenIM™ substrates balance cost, reliability, and performance, making them suitable for most industrial and electronic applications.

Why Choose Accuratus GreenIM™?

Accuratus has decades of experience in advanced ceramic material development. With precision manufacturing, ISO-certified processes, and global technical support, GreenIM™ substrates deliver unmatched consistency and reliability.

Customized sizes and thicknesses available

Compatible with DBC (Direct Bonded Copper) and DPC (Direct Plated Copper) metallization

Proven track record in semiconductor and electronics industries

Learn more about ceramic materials

Learn more about ceramic materials

The American Ceramic Society, ACerS)

👉 https://ceramics.org/Materials Project – Alumina Database (Lawrence Berkeley National Laboratory)

👉 https://materialsproject.org/materials/mp-1143/NASA Technical Reports – Ceramic Substrates in Electronics

👉 https://ntrs.nasa.gov/IEEE Xplore Digital Library (Electronics & Substrate Research)

👉 https://ieeexplore.ieee.org/AZoM – Alumina (Aluminum Oxide) Material Information

👉 https://www.azom.com/article.aspx?ArticleID=52

Conclusion

GreenIM™ alumina substrates provide the perfect balance of cost-effectiveness, thermal performance, and dielectric reliability. Whether used in semiconductor packaging, RF communication, or power electronics, GreenIM™ delivers a trusted solution for advanced applications.

Contact Us

👉Website: nmmech.com

👉Email: jack@nmmech.com

GIM

GIM

Learn more about ceramic materials

Learn more about ceramic materials