AMB Ceramic Metallized Substrate Product Introduction

AMB Ceramic Metallized Substrate Product Introduction

(Активная металлическая паяльная керамическая подложка)

In today’s rapidly evolving electronics industry, high-performance and high-reliability electronic components and materials are crucial for driving technological innovation and product upgrades. АМБ (Active Metal Brazing) ceramic metallized substrates, as an advanced electronic packaging material, are demonstrating immense potential in sectors such as semiconductors, Автомобильная электроника, aerospace, and renewable energy, thanks to their superior performance and diverse application prospects.

Обзор продукта

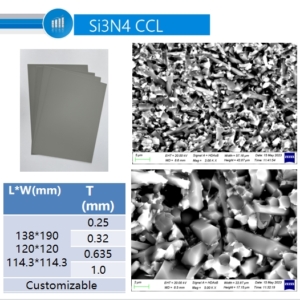

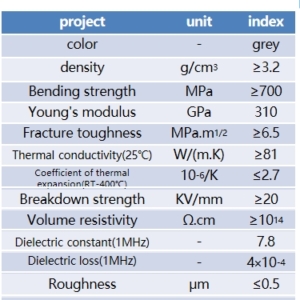

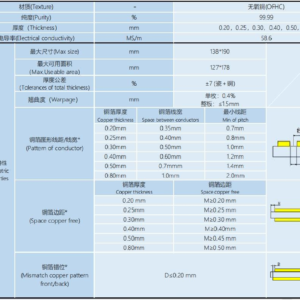

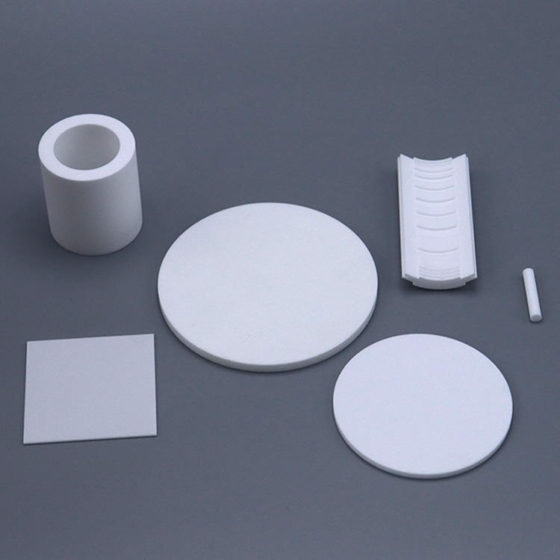

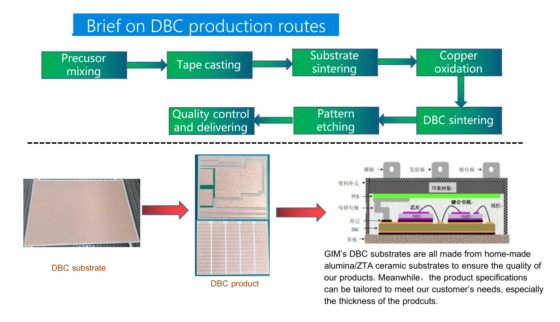

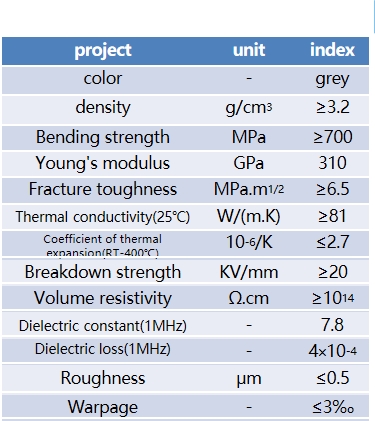

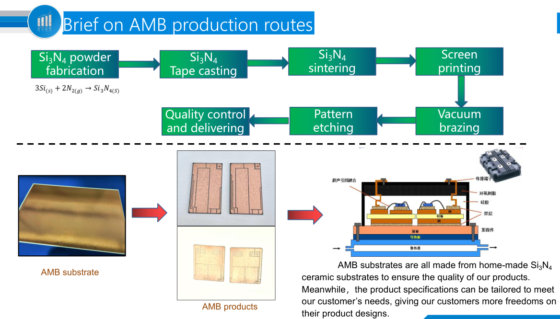

AMB ceramic metallized substrates are composite materials that combine ceramics (например., alumina, Нитрид алюминия) with metals (например., copper, nickel) through active metal brazing technology. These substrates inherit the high hardness, high wear resistance, высокая теплоизоляция, and excellent thermal stability of ceramic materials, while also incorporating the good electrical conductivity and thermal conductivity of metallic materials. This achieves a perfect balance between electrical, mechanical, and thermal properties.

Product Features

High Thermal Conductivity: AMB ceramic metallized substrates utilize high-thermal-conductivity ceramic materials as the base. Through optimized brazing processes, efficient heat conduction between ceramics and metals is achieved, allowing the substrate to rapidly dissipate heat and ensure the stable operation of electronic components.

High Reliability: Active metal brazing technology forms strong chemical bonds between ceramics and metals, providing excellent bond strength and peel resistance. Even under extreme temperature, humidity, and mechanical stress conditions, the substrate maintains stable performance, ensuring long-term reliability of electronic products.

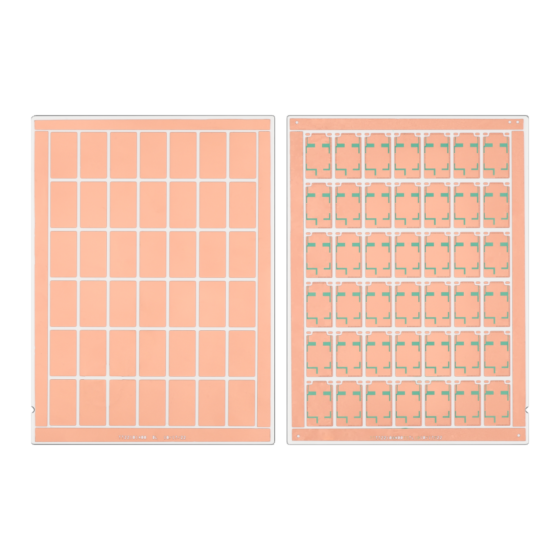

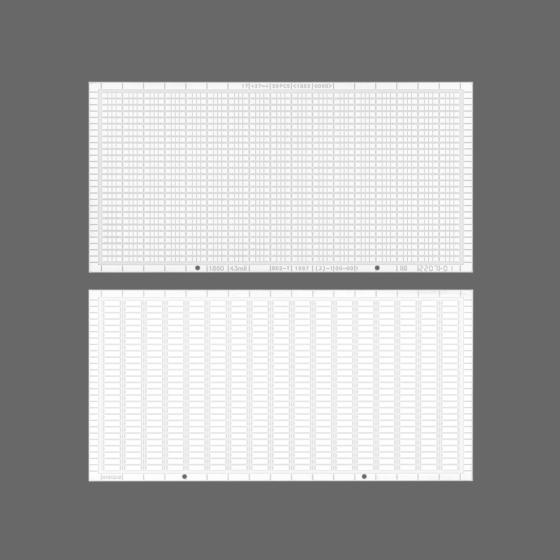

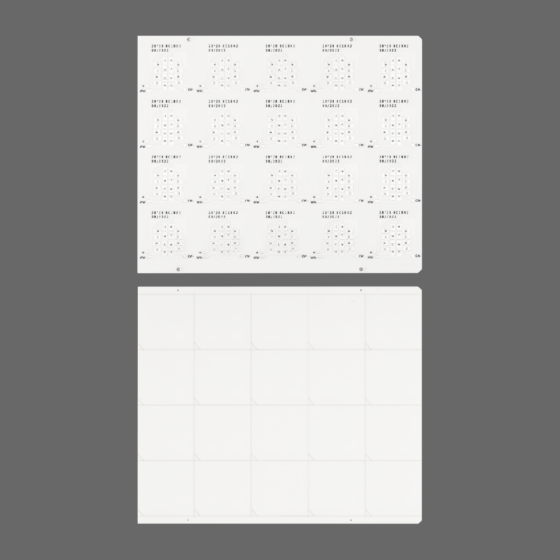

High-Precision Processing: AMB ceramic metallized substrates utilize advanced processing technologies and equipment to achieve high-precision circuit fabrication and surface treatment, meeting the design requirements of complex electronic circuits. Дополнительно, the flatness and thickness uniformity of the substrate are strictly controlled, ensuring precise installation and connection of electronic components.

Environmentally Friendly and Energy-Efficient: AMB technology employs lead-free, cadmium-free, and other environmentally friendly materials, complying with international environmental standards. Furthermore, due to the substrate’s excellent thermal conductivity, it can significantly reduce the energy consumption and cooling costs of electronic products, achieving green and energy-efficient production and usage.

Application Areas

Application Areas

AMB ceramic metallized substrates, with their superior performance, have found widespread applications in multiple fields:

Semiconductor Packaging: The high thermal conductivity and excellent electrical properties of AMB substrates make them ideal for the semiconductor packaging industry. They can effectively dissipate heat generated by chips, protecting them from overheating damage and improving packaging reliability and lifespan.

Automotive Electronics: With the increasing electrification of automotive systems, the reliability and thermal management requirements for electronic components are also rising. AMB substrates, with their high thermal conductivity and vibration resistance, have become the preferred material in automotive electronics, applicable to key components such as engine control units, in-car entertainment systems, and battery management systems.

Aerospace: In the aerospace sector, electronic components need to withstand extreme environmental conditions, such as high temperatures, high pressures, and intense radiation. The high hardness, high wear resistance, and excellent thermal stability of AMB substrates make them indispensable materials in aerospace electronic equipment.

Renewable Energy: In the renewable energy sector, such as solar PV inverters and wind power control systems, the high thermal conductivity and reliability of AMB substrates are crucial for improving system efficiency and stability.

Заключение

AMB ceramic metallized substrates, as high-performance electronic packaging materials, are becoming an important force in driving technological innovation and product upgrades in the electronics industry, thanks to their superior performance and diverse application prospects. We are committed to providing customers with high-quality AMB substrate products and services, helping them stand out in the fiercely competitive market and jointly creating a brighter future.

✅Contact us:

website: www.nmmech.com

Отправить по электронной почте: jack@nmmech.com

More industry information:

🌐 1. Advanced Materials / Precision Ceramics

External Link: https://www.azom.com

Description :

Learn more about the latest trends in advanced ceramics and precision materials from AZoM, a global materials science hub that provides insights into material innovations, applications, and manufacturing technologies.

🚀 2. Aerospace Industry

External Link: https://www.nasa.gov

Description:

The aerospace industry relies heavily on high-performance ceramics. Visit NASA to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

⚙️ 3. Electronics Industry

External Link: https://www.ieee.org

Description:

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance. IEEE is a trusted global organization that drives innovation in electrical and electronic engineering.

💡 4. Semiconductor Industry

External Link: https://www.semiconductors.org

Description:

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the Semiconductor Industry Association (SIA).

🚗 5. Automotive Industry

External Link: https://www.sae.org

Description:

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries. Visit SAE International for standards and innovations driving automotive engineering forward.

🏥 6. Medical & Healthcare

External Link: https://www.fda.gov/medical-devices

Description:

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance. The U.S. FDA Medical Devices Center provides regulatory and research information in this field.

⚡ 7. New Energy / Renewable Energy

External Link: https://www.energy.gov

Description:

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics. Visit the U.S. Department of Energy (DOE) for innovations and materials research in sustainable energy technologies.

ГИМ

ГИМ