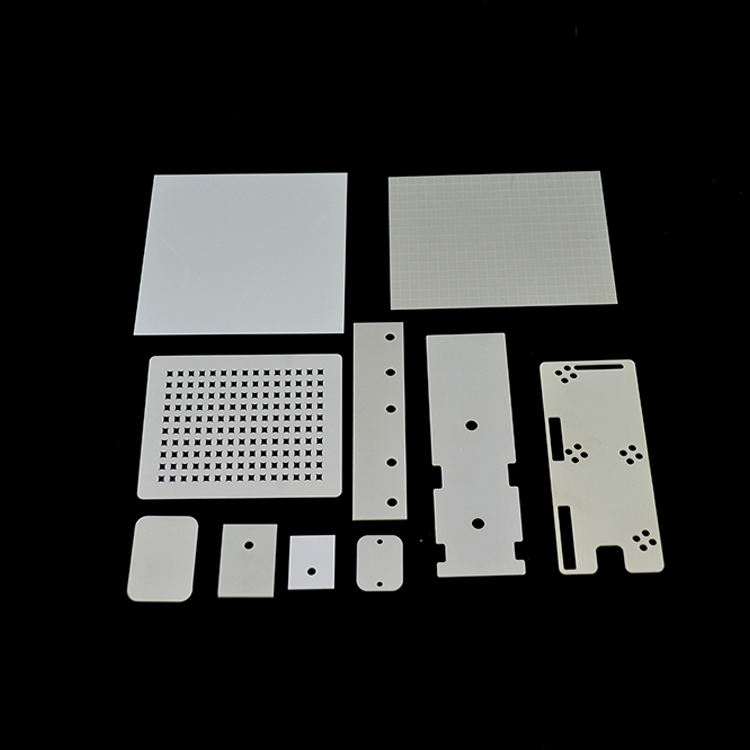

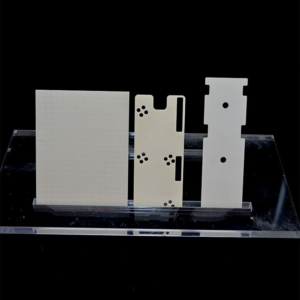

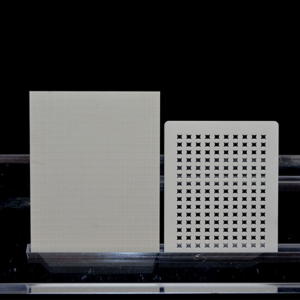

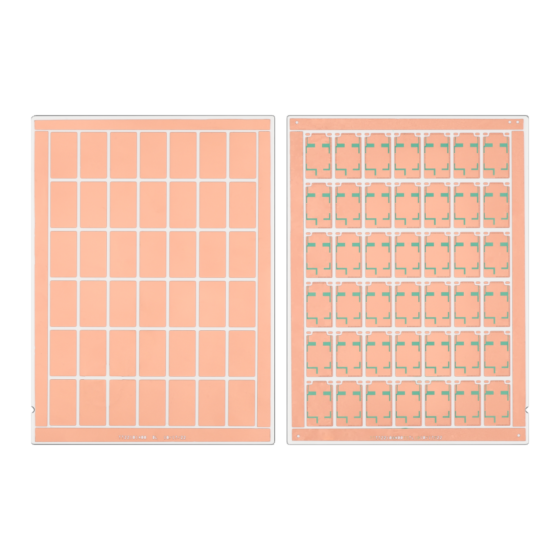

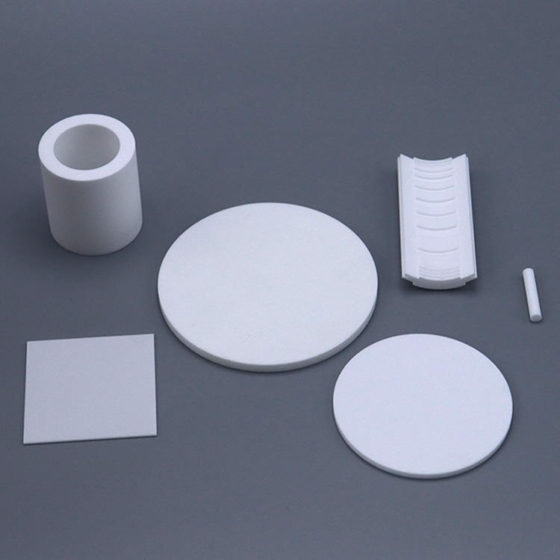

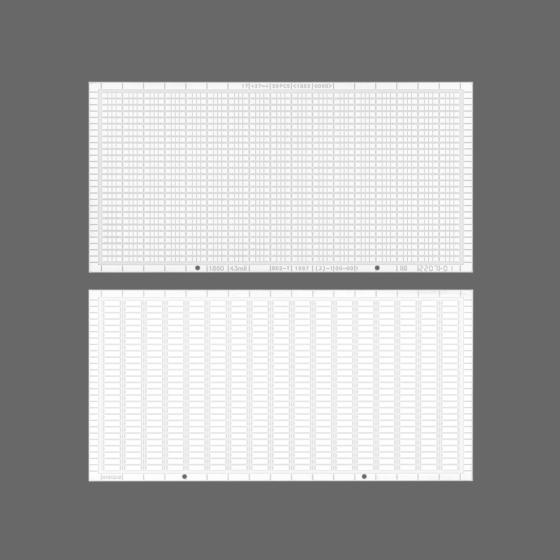

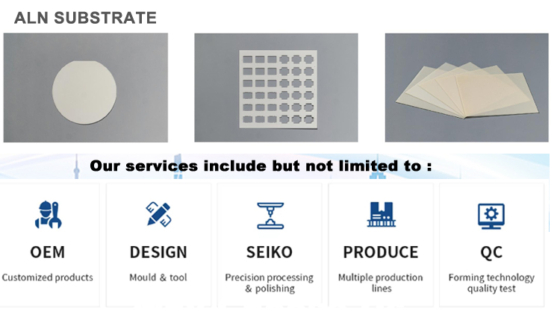

Customized High Thermal Conductivity Aluminum Nitride (Aln) Ceramic Substrate

Product Highlights

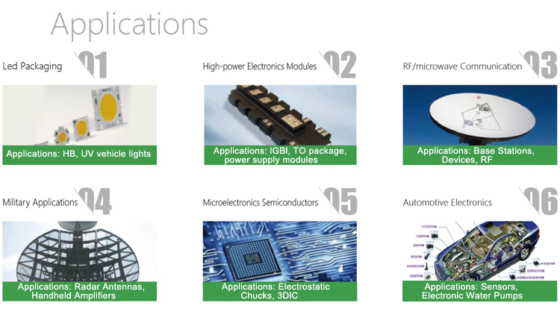

Aluminum nitride (Aln) ceramic substrate is a next-generation material known for its exceptional thermal conductivity and excellent insulation properties. With the rising demand for efficient thermal management in high-power and high-density electronic applications, AlN has become a preferred choice for advanced LED packaging, large-scale integrated circuits, semiconductor modules, and power devices.

Key Features of Aluminum Nitride (Aln) Substrate:

Key Features of Aluminum Nitride (Aln) Substrate:

Exceptional Thermal Conductivity

Offers high thermal conductivity ranging from 140 to 200 W/m·K, ensuring superior heat dissipation in demanding applications.Excellent Electrical Insulation

High dielectric strength and low dielectric constant make it ideal for use in electronic insulation environments.Low Thermal Expansion (CTE)

Its low coefficient of thermal expansion closely matches that of silicon and other semiconductor materials, minimizing thermal stress and enhancing long-term reliability.Outstanding Chemical Stability

Resistant to most acids and alkalis, providing strong chemical durability—excluding reactions with strong bases and hydrofluoric acid.Robust Mechanical Strength

Capable of withstanding high mechanical and thermal loads, making it suitable for harsh environments and high-performance applications.

Aluminum nitride substrate PerformanceIndex

| Item | Unit | Reference Value | Test method |

| Thermal conductivity | W/m・K | >170 | Transient plane source method |

| Surface roughness | μm | <0.6 | Stylus surface roughness tester |

| Warpage | / | <2.5‰ | Glass gauge |

| Apparent density | g/cm3 | ≥3.26 | Drainage method |

| Bending strength | Mpa | >300 | Three-point bending resistance method |

| Volume resistance | Ω・cm | 1.5×1013 (TYP) | Volume resistance gauge |

| Dielectric constant | @1MHz | 8.9 (TYP) | Impedance method |

| Dielectric loss | @1MHz | 4.6×10-4(TYP) | Impedance method |

| Break down voltage | Kv/mm | 36.85(TYP) | DC power method |

| Coefficient of linear expansion | 1×10-6/℃ | 4.75(TYP) | Thermomechanical analysis |

✅Contact us:

website: www.nmmech.com

Email: jack@nmmech.com

More industry information:

🌐 1. Advanced Materials / Precision Ceramics

External Link: https://www.azom.com

Description :

Learn more about the latest trends in advanced ceramics and precision materials from AZoM, a global materials science hub that provides insights into material innovations, applications, and manufacturing technologies.

🚀 2. Aerospace Industry

External Link: https://www.nasa.gov

Description:

The aerospace industry relies heavily on high-performance ceramics. Visit NASA to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

⚙️ 3. Electronics Industry

External Link: https://www.ieee.org

Description:

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance. IEEE is a trusted global organization that drives innovation in electrical and electronic engineering.

💡 4. Semiconductor Industry

External Link: https://www.semiconductors.org

Description:

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the Semiconductor Industry Association (SIA).

🚗 5. Automotive Industry

External Link: https://www.sae.org

Description:

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries. Visit SAE International for standards and innovations driving automotive engineering forward.

🏥 6. Medical & Healthcare

External Link: https://www.fda.gov/medical-devices

Description:

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance. The U.S. FDA Medical Devices Center provides regulatory and research information in this field.

⚡ 7. New Energy / Energia renovável

External Link: https://www.energy.gov

Description:

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics. Visit the U.S. Department of Energy (DOE) for innovations and materials research in sustainable energy technologies.