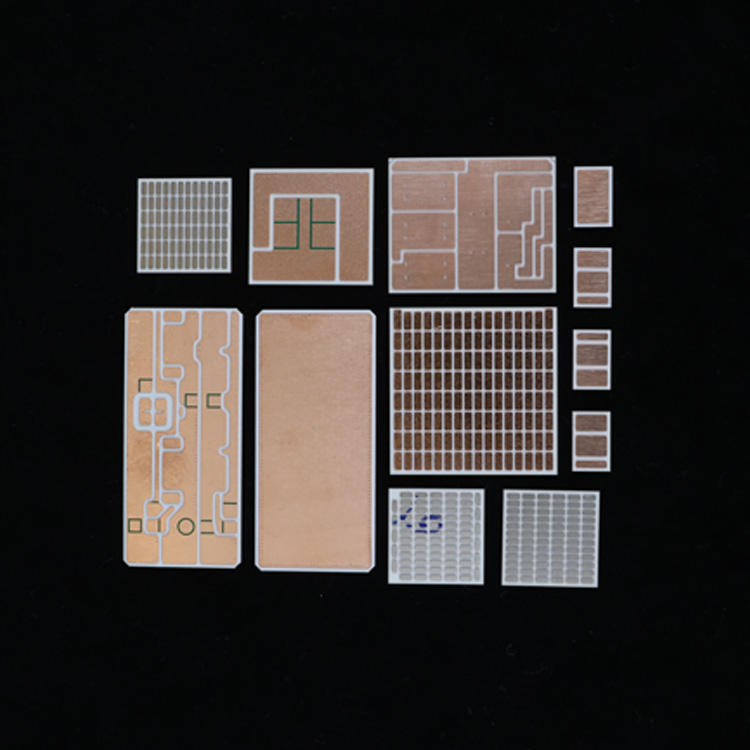

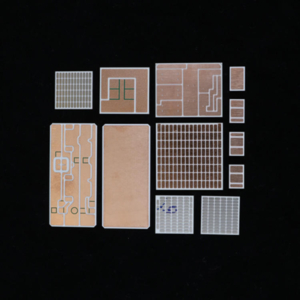

Direct Bonded Copper (DBC) Alumina Ceramic Substrate

Direct Bonded Copper (DBC) Alumina Ceramic SubstrateWarning/Disclaimer

This product has obtained relevant product qualifications/licenses for certain applicable countries.

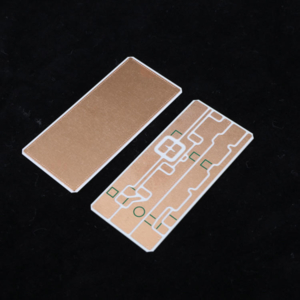

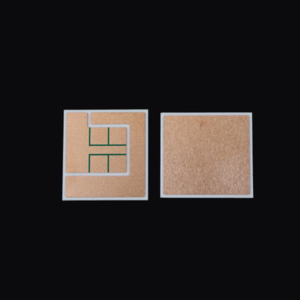

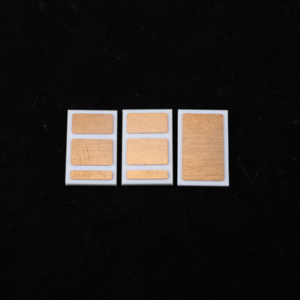

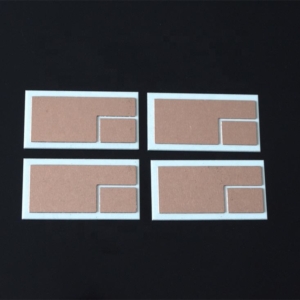

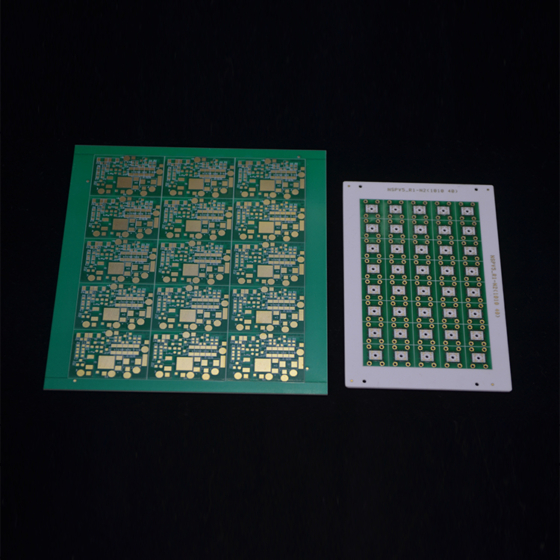

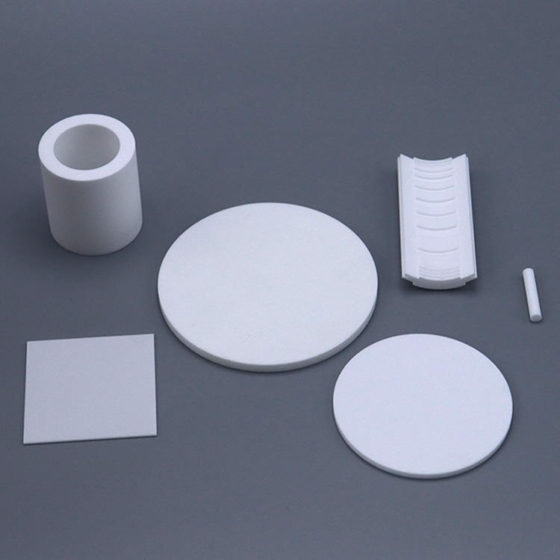

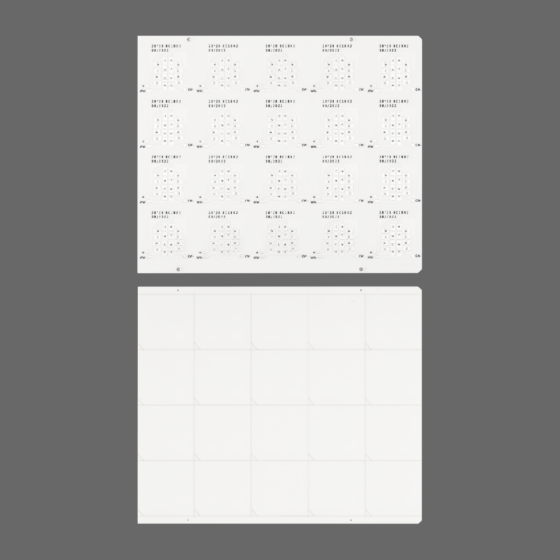

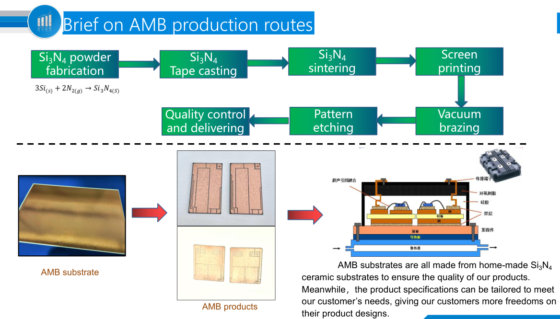

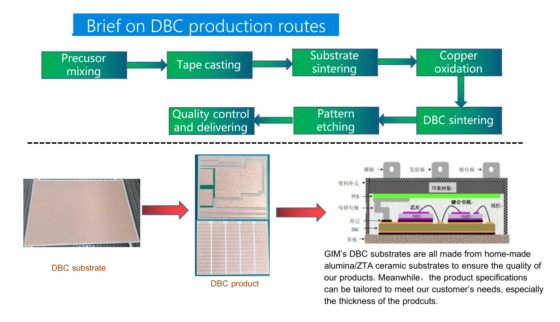

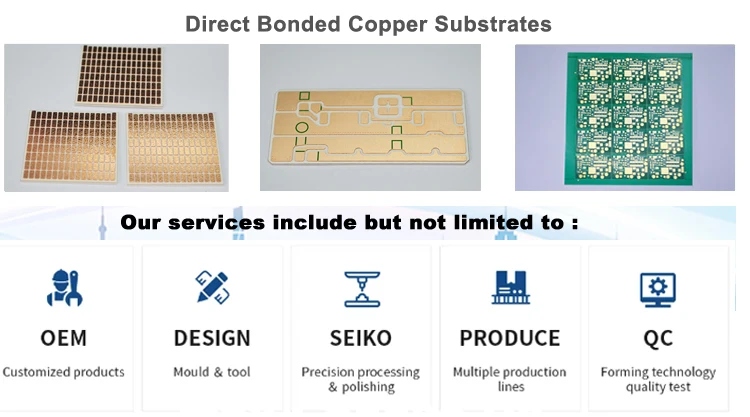

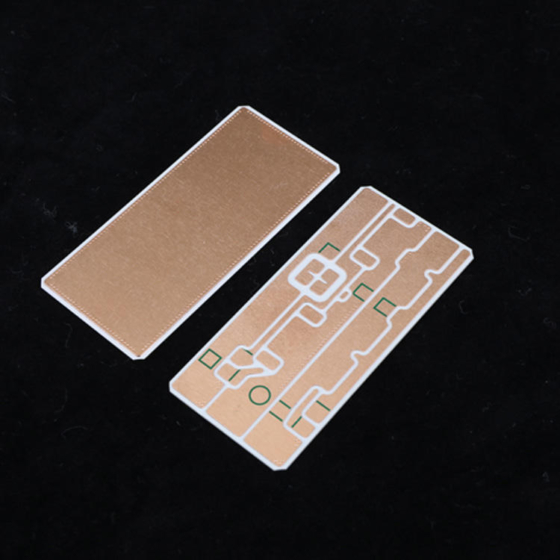

DBC ceramic substrate is a high-performance material used in power electronics. It combines direct bonded copper (DBC) with a ceramic base, offering excellent thermal conductivity and electrical insulation. This substrate is ideal for applications requiring efficient heat dissipation, such as LED lighting and automotive modules. Its robust structure ensures reliability in demanding environments.

Item | Unit | Si3N4 | AlNの | ZTA | BeO |

Density | g/m³ | 3.2 | 3.3 | 4 | 3 |

Thermal Conductivity | W/m.K@25℃ | ≥80 | ≥170 | ≥27 | ≥250 |

Coefficient of Thermal Expansion | X10 -6 /K (20℃-300℃) | ≤2.6 | ≤4.3 | ≤7.5 | ≤9 |

Flexural Strength | MPa | ≥700 | ≥450 | ≥500 | ≥190 |

Dielectric Strength | KV/mm | ≥15 | ≥15 | ≥15 | ≥15 |

Dielectric Loss | 1MHz | 0.0003 | 0.0003 | 0.0003 | 0.0003 |

Dielectric Constant | 1MHz | 9 | 9 | 10.5 | 6.9 |

Volume Resistivity | Ω·cm@ 20 °C | 1014 | 1014 | 1014 | 1014 |

Young’s Modulus | Gpa | 320 | 320 | 310 | / |

Item | Unit | Performance |

Thickness | ミリメートル | 0.127/0.2/0.25/0.3/0.4/0.5/0.8 |

Oxygen Content | % | ≤0.001 |

Surface Hardness | HV3 | 90-120(Post-Copper Cladding:45-55) |

Conductivity | MS/m | 58.6 |

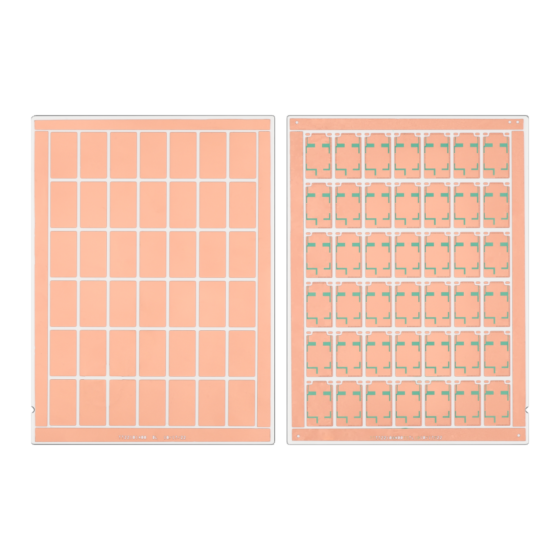

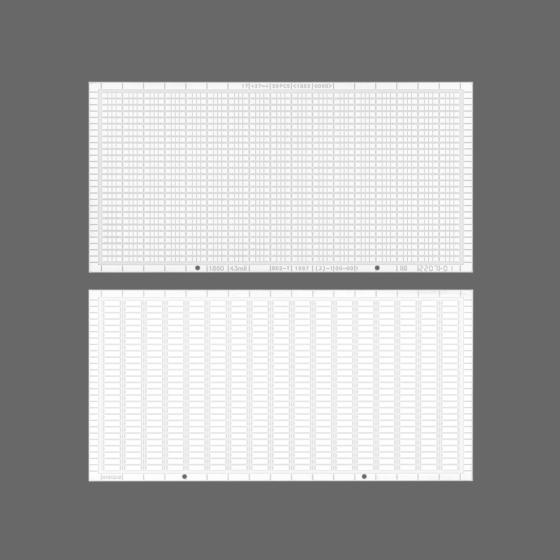

0.127ミリメートル | 0.2ミリメートル | 0.25ミリメートル | 0.3ミリメートル | 0.4ミリメートル | 0.5ミリメートル | 0.8ミリメートル | |

0.25ミリメートル | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 |

0.32ミリメートル | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA |

0.38ミリメートル | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

0.635ミリメートル | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

1.0ミリメートル | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

2.0ミリメートル | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

Direct Bonded Copper Ceramic Substrates Material Property:

Direct Bonded Copper Ceramic Substrates Material Property:

– Low Thermal Expansion

– High Strength

– High Thermal Conductivity

– High Wettability for Solder

– Power Electronics: IGBT, MOSFET, Thyristor Module, Solid-state Relay, Diode, Power Transistors

– Automotive: ABS, Power Steering, DC/DC Converter, LED Lighting, Ignition Control

– Home Appliance: Air Conditioner, Peltier Cooler

– Environmental Technology: Local Power Generation, Electric Vehicle, Traction Control System, Photovoltaic Units, Wind Power

– Industrial: LED Displays, Welding Machine

– Aerospace: Laser, Power Supply for Satellites and Aircrafts

– PC/IT: Power Supply, UPS System

✅Contact us:

website: www.nmmech.com

電子メール: jack@nmmech.com

More industry information:

🌐 1. Advanced Materials / Precision Ceramics

External Link: https://www.azom.com

Description :

Learn more about the latest trends in advanced ceramics and precision materials from AZoM, a global materials science hub that provides insights into material innovations, applications, and manufacturing technologies.

🚀 2. Aerospace Industry

External Link: https://www.nasa.gov

Description:

The aerospace industry relies heavily on high-performance ceramics. Visit NASA to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

⚙️ 3. Electronics Industry

External Link: https://www.ieee.org

Description:

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance. IEEE is a trusted global organization that drives innovation in electrical and electronic engineering.

💡 4. Semiconductor Industry

External Link: https://www.semiconductors.org

Description:

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the Semiconductor Industry Association (SIA).

🚗 5. Automotive Industry

External Link: https://www.sae.org

Description:

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries. Visit SAE International for standards and innovations driving automotive engineering forward.

🏥 6. Medical & Healthcare

External Link: https://www.fda.gov/medical-devices

Description:

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance. The U.S. FDA Medical Devices Center provides regulatory and research information in this field.

⚡ 7. New Energy / Renewable Energy

External Link: https://www.energy.gov

Description:

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics. Visit the U.S. Department of Energy (DOE) for innovations and materials research in sustainable energy technologies.