High-Purity Alumina Ceramic Disc for 1/2″–3/4″ Brass Tap Cartridges and Valves –

High-Purity Alumina Ceramic Disc for 1/2″–3/4″ Brass Tap Cartridges and Valves –

Wear Resistant

| Attributes | Details |

|---|---|

| Matériel | Alumina Ceramic (Alumina ceramics,95%–99%) |

| Place of Origin | Guangdong, Chine |

| Type | Ceramic Parts |

| Application | Industrial Ceramic / Valve Core / Tap Ceramic Disc |

| Model Number | XTL |

| Brand Name | GIM |

| Processing Service | Punching / OEM Service Available |

| Color | Pure White / Black |

| Hardness | 1100 Hv5 |

| Flatness | ≤ 0.6 μm |

| Surface Roughness (Ra) | ≤ 0.25 μm |

| Fonction | Valve Core |

| Used For | Tap Ceramic Disc |

| Diameter Tolerance | < ±0.02 mm |

| Density | 3.6–3.9 g/cm³ |

| Vickers Hardness | 11–15 |

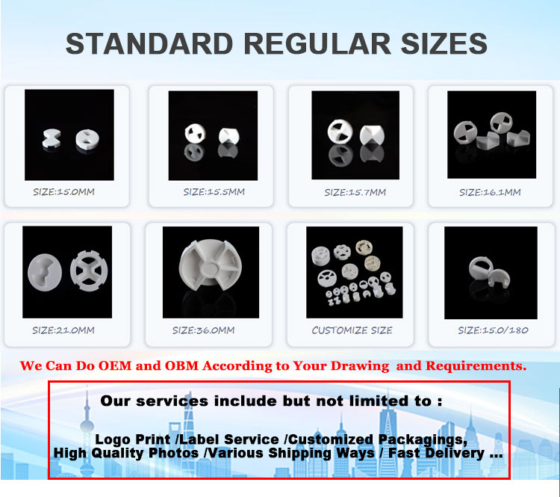

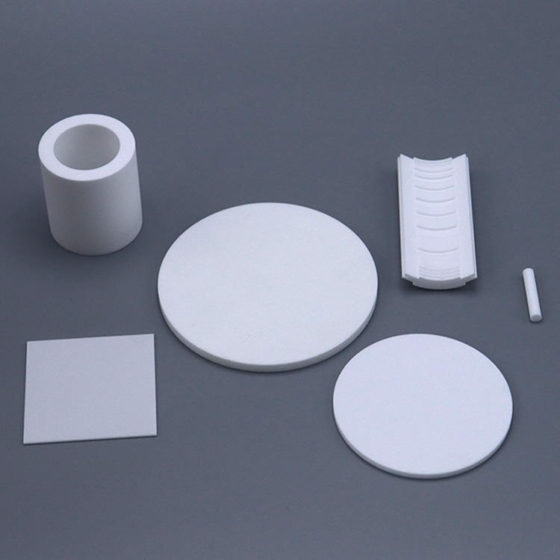

| Specification | Outer Diameter (OD): 11.5 mm – 32 mm |

| Frictional Endurance | 300,000 – 500,000 times |

| OEM Service | Supported |

| Sample | Free Sample Available |

| Selling Units | Single Item |

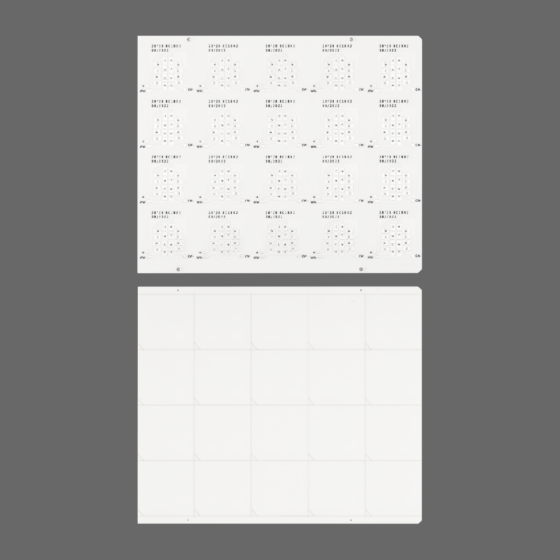

Main Advantages of Alumina Ceramic Disc Cartridge

Main Advantages of Alumina Ceramic Disc Cartridge

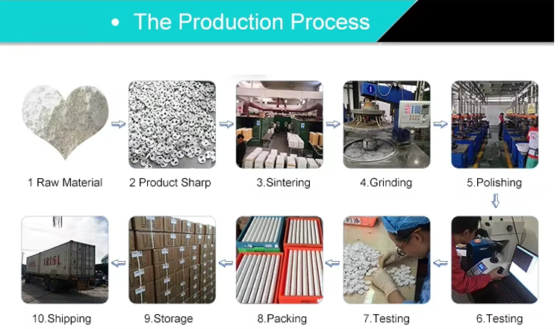

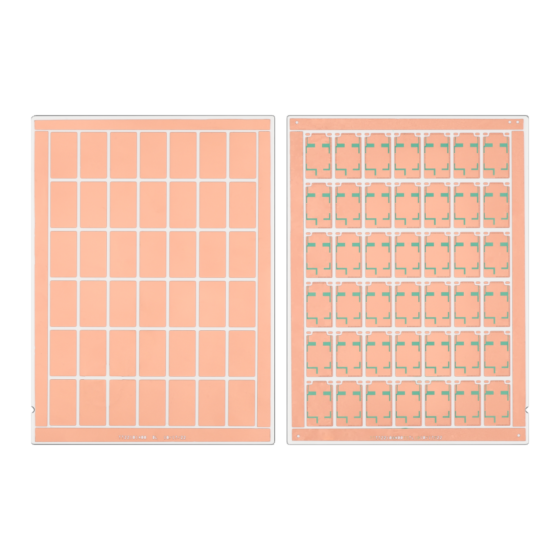

Our ceramic disc cartridges are made of high-purity 95% Al₂O₃ alumina ceramic, primarily used in temperature control valves, diverter valves, surf and massage bathtub mixers, and LPG valves. These ceramic discs offer excellent sealing performance, high compressive and flexural strength, and outstanding durability—tested for over 500,000 cycles.

Key Properties of Alumina Ceramic Discs

Excellent Chemical Resistance

Resistant to acid, alkali, and chemical cleaning agents.High Pressure Resistance

Maintains performance under high-pressure conditions without deformation or leakage.Self-Cleaning Surface

Effectively resists lime scale build-up even at high water temperatures, prolonging service life.Corrosion and Abrasion Resistance

Non-corrosive material with exceptional wear resistance, ensuring long-term reliability.

Applications of Ceramic Disc Cartridges

Temperature control valves

Diverter valves for bathtubs and spa systems

LPG and gas valves

Espresso and coffee machines

Single-handle and double-handle faucet cartridges

Titration equipment and chemical analyzers

Medical devices and equipment

Ceramic seals and regulator discs

Sanitary fittings and special-purpose valves

Refrigerant valves and solid/gas dosing systems

Packaging & Delivery

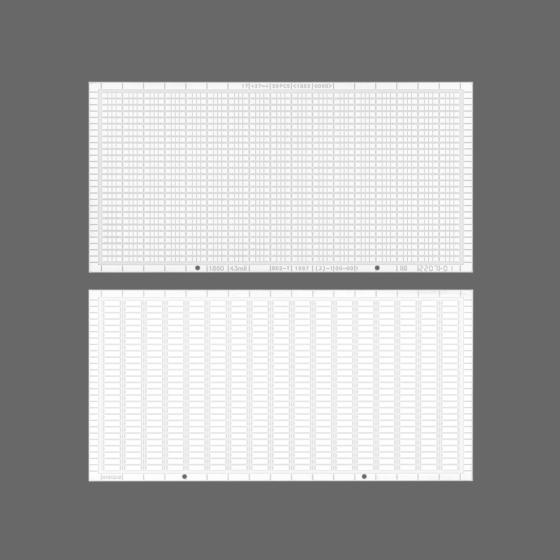

Standard Packaging: Each qualified product is packed in a protective plastic bag and carton box.

Fine Packaging Option: Individual plastic bubble casing, then placed into sturdy cartons for maximum protection.

Paper Wrapping Available: For added cleanliness and moisture resistance.

Customization: OEM packaging and logo printing available upon request.

Performance For Industrial Ceramic | |||||

Item | Unit | 95Al2O3 | 96 Al2O3 | 99 Al2O3 | |

Physical Characteristics | Heat resistance | °C | 1500 | 1550 | 1800 |

Bulk density | g/cm3 | 3.6 | 3.6 | 3.9 | |

Water absorption | % | 0 | 0 | 0 | |

Mechanical Characteristics | Flexural strength | Mpa | 320 | 340 | 360 |

Hardness vickers | Gpa | 12.2 | 13.5 | 15.6 | |

Elastic modulus | Gpa | 280 | 320 | 370 | |

Poisson’s ratio | 0.22 | 0.23 | 0.23 | ||

Thermal Characteristics | Linear expansion coefficient | (20-500°C) 10-6/°C | 7.1 | 7.2 | 8 |

Thermal conductivity | w/(m.k) | 16 | 24 | 32 | |

Specific Heat | *10-3J/(kg*K) | 0.78 | 0.78 | 0.9 | |

Electrical Characteristics | Dielectric constant (1MHZ) | – | 9 | 9.4 | 9.9 |

Dielectric loss angle | *10-4 | 15 | 5 | 1 | |

Dielectric strength | *106V/m | 12 | 15 | 15 | |

✅Contact us:

website: www.nmmech.com

Messagerie électronique: jack@nmmech.com

More industry information:

🌐 1. Advanced Materials / Precision Ceramics

External Link: https://www.azom.com

Description :

Learn more about the latest trends in advanced ceramics and precision materials from AZoM, a global materials science hub that provides insights into material innovations, Applications, and manufacturing technologies.

🚀 2. Aerospace Industry

External Link: https://www.nasa.gov

Description:

The aerospace industry relies heavily on high-performance ceramics. Visit NASA to explore how ceramic materials are used in propulsion systems, thermal protection, and structural components in space exploration.

⚙️ 3. Electronics Industry

External Link: https://www.ieee.org

Description:

The electronics and semiconductor sectors depend on materials with high dielectric strength and insulation performance. IEEE is a trusted global organization that drives innovation in electrical and electronic engineering.

💡 4. Semiconductor Industry

External Link: https://www.semiconductors.org

Description:

Discover how advanced ceramics contribute to semiconductor manufacturing — from wafer handling to plasma etching — at the Semiconductor Industry Association (SIA).

🚗 5. Automotive Industry

External Link: https://www.sae.org

Description:

The automotive industry increasingly adopts advanced ceramic components for fuel systems, sensors, and EV batteries. Visit SAE International for standards and innovations driving automotive engineering forward.

🏥 6. Medical & Healthcare

External Link: https://www.fda.gov/medical-devices

Description:

Advanced ceramics play a vital role in medical implants and devices due to their bio-compatibility and wear resistance. The U.S. FDA Medical Devices Center provides regulatory and research information in this field.

⚡ 7. New Energy / Renewable Energy

External Link: https://www.energy.gov

Description:

In the renewable energy sector, ceramics are used for high-temperature fuel cells and power electronics. Visit the U.S. Department of Energy (DOE) for innovations and materials research in sustainable energy technologies.